WHICH SOLUTION IS RIGHT FOR YOU?

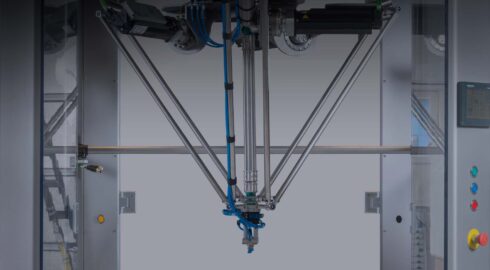

A Complete Range of Tray Denesting, Tray Loading & Handling Equipment

KEY NUMBERS

Quality Quantified

We know that the hygiene, efficiency, and reliability of tray denesting and handling automation

matter to our customers. But don’t take our word for it, take our numbers.

Our customers rely on QUPAQ to denest and handle over 10,000,000,000 trays annually. Bon appetit.

Dedicated to denesting and handling solutions for over a quarter of a century. We understand trays.

QUPAQ is the world leader in tray denesting and handling, and we’ve got the patents to prove it.

SEGMENTS WE SERVE

If You Can Make It, We Can Pack It

QUPAQ has broad and deep experience serving customers across all major food product categories packed in trays.